DIGITAL TRANSFORMATION IS

SLOW AND EXPENSIVE

BUT THERE IS A WAY TO LESSEN THE PAIN

DIGITAL TRANSFORMATION IS

SLOW AND EXPENSIVE

BUT THERE IS A WAY TO LESSEN THE PAIN

Manufacturers are using digital twin technology to help them modernise. Service organisations can do the same.

It may seem counter-intuitive, but one of Gartner’s top strategic predictions for 2021 is that smaller organisations will have more digital transformation success than larger ones.

In fact, Gartner’s report suggests that, going forward, digital transformation initiatives in large organisations will take twice as long and cost twice as much as anticipated. This is because existing digital services are typically reliant on a high degree of operational interdependence.

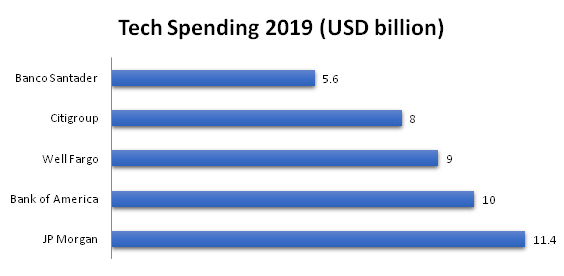

The more action already taken to digitise, the more likely it is that the infrastructure will be complex and costly to untangle. Meanwhile, the pressure is greatest on large organisations to demonstrate their ability to innovate. It is no wonder that tech spending by some of the world’s largest banks is already at breathtaking levels.

Source: Bloomberg

If indeed these numbers are set to double, then there must be a better strategy to determine the outcome of modernisation initiatives. This is where banks may want to look to manufacturers for the way forward. Unlike banks, manufacturers have long had to contend with the challenge of testing new and expensive ideas before productionising the real thing.

In recent times, this has been done by creating a digital replica of their products. These replicas, now commonly referred to as “digital twins”, let manufacturers trial product innovations and make tweaks in the virtual realm without impacting existing production lines. Once the products are physically manufactured, digital twin technology continues to help manufacturers run and maintain them.

It is said that digital twin technology was first used by NASA to simulate space programming, and the conditions on board Apollo 13. Today, the technology can provide highly accurate simulations of a process or object, based on comprehensive data that the original NASA scientists could only have dreamt of. It is estimated that by the end of this year, up to 60% of the world’s manufacturers will be leveraging digital twin technology to monitor product performance and quality.

Tesla is one of the best known modern users of this technology. Every Tesla car has a digital twin, and a tight coupling allows data to be exchanged between the two throughout the car’s lifecycle. Not only does this allow Tesla to collect valuable information about its cars in real world environments, but also to predict problems using AI, and to fix problems using digital modelling.

Now digital twin concepts have evolved from product assembly lines to banking, government and healthcare services. In this re-imagining of the digital twin (let’s call it Digital Twin 2.0), an integrated and high integrity representation of an organisation’s data is instantly updated and made available.

Like a manufacturer, the Digital Twin 2.0 lets service organisations try out new software and digital processes alongside existing ones. They can also help predict outcomes and optimise deployments, and are therefore invaluable for large scale exercises such as infrastructure upgrades, or new service launches, while ensuring that normal routines are not affected.

However the Digital Twin 2.0 is not powered by data from physical devices and IoTs, but from human interactions in the real world. These can be transactions, behaviours or preferences. But for the Digital Twin 2.0 to demonstrate value, it must meet certain pre-requisites:

- Similar to its 1.0 predecessor, it must offer three levels of connectivity, ie to systems, things and people. For the Digital Twin 2.0, this can be interpreted as core transaction systems, external data sources, and data applications.

Digital Twin 2.0: Levels of Connectivity

- It must enable bi-directional data flows, and therefore communication across all four layers, in real time or near real time.

- It must enable data to be stored in a way that supports the original process or asset lifecycle, while facilitating innovation.

- It must act as a single source of truth for multiple objectives, and therefore multiple users and personas.

- Tight controls must be in place to ensure replicated data is secure, reliable and auditable.

Perhaps the starkest contrast between a digital twin designed for manufacturing, and one for services such as banking, is that it is device-free. By capturing data generated by customers’ everyday activities, the Digital Twin 2.0 enables organisations to model infrastructure and customer needs across a wide variety of circumstances. This means accelerated service launches and digital transformation under controlled conditions.

Perhaps this can avert the Gartner curse?